Bring combined sensor and SaaS technology to industries that have been slow

to benefit from the rapid pace of technology innovation over the past

decade.

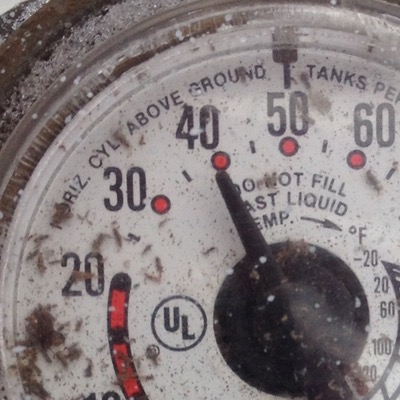

“Analog” industries such as Agriculture, Forestry, Fishing, Construction,

Trucking, Manufacturing, Oil and Gas, and many others are yet to fully benefit

from technological innovation in the way that information-based and

service-based industries have. These “analog” industries require physical

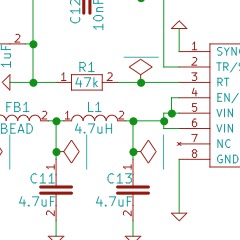

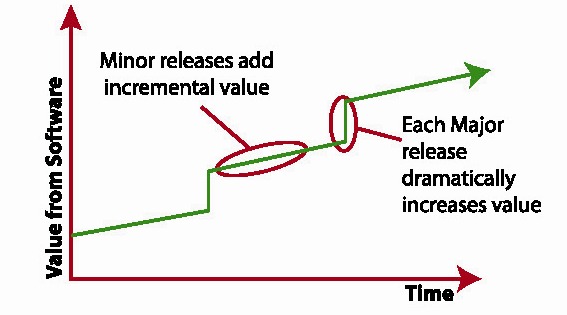

hardware to interface with the software world. But hardware development is

expensive, complex, and iteration takes too long compared to software

development.

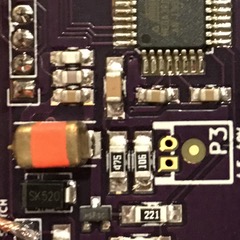

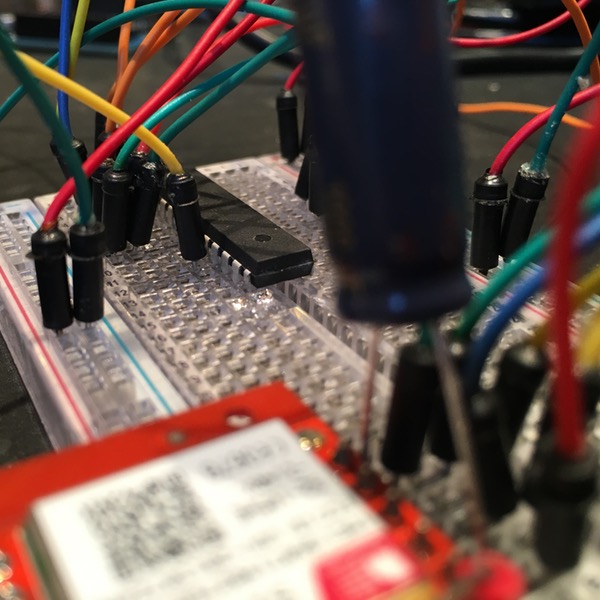

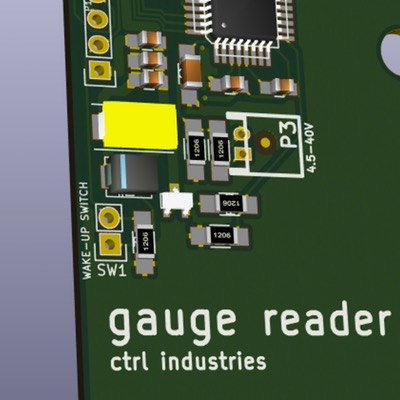

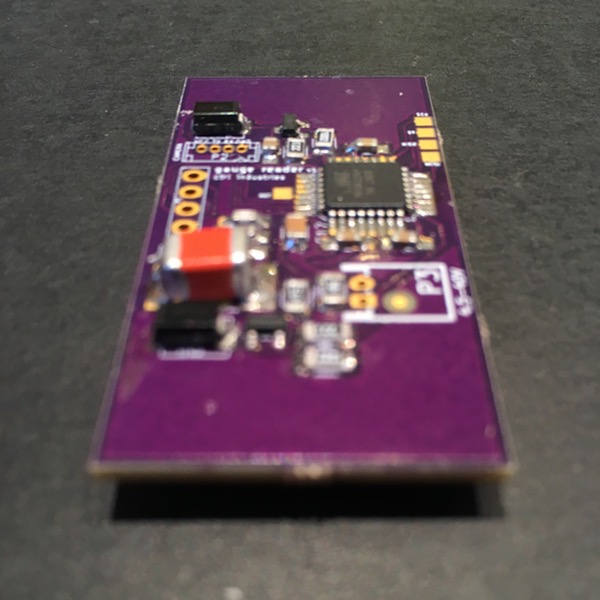

But now hardware development is changing. Prototyping cycles have shortened,

electronic components can be ordered in small quantities quickly and cost

effectively, and there has been a surge in simple-to-program microcontrollers.

The production cost for a simple wireless sensor device can be less than $25,

and hardware development time can be reduced from a year to months or even

weeks! The plethora of Internet-of-Things consumer devices is one result of

these changes (fitness trackers,

wifi-connected light bulbs, smart refrigerators). However the path to

profit for Internet-of-Things consumer devices is not very clear. Are people

really willing to pay a monthly service fee to monitor their refrigerator? Or

install a new phone app for every device in their house?

On the other hand, there is a clear value proposition for Internet-of-Things

innovations for businesses, and more specifically, “analog” businesses.

Internet-of-Things devices and services can help them respond to customer

service problems faster, mitigate business risks, reduce labor expenses, reduce

energy expenses, improve coordination with suppliers, and improve understanding

of equipment health. The list goes on and on.